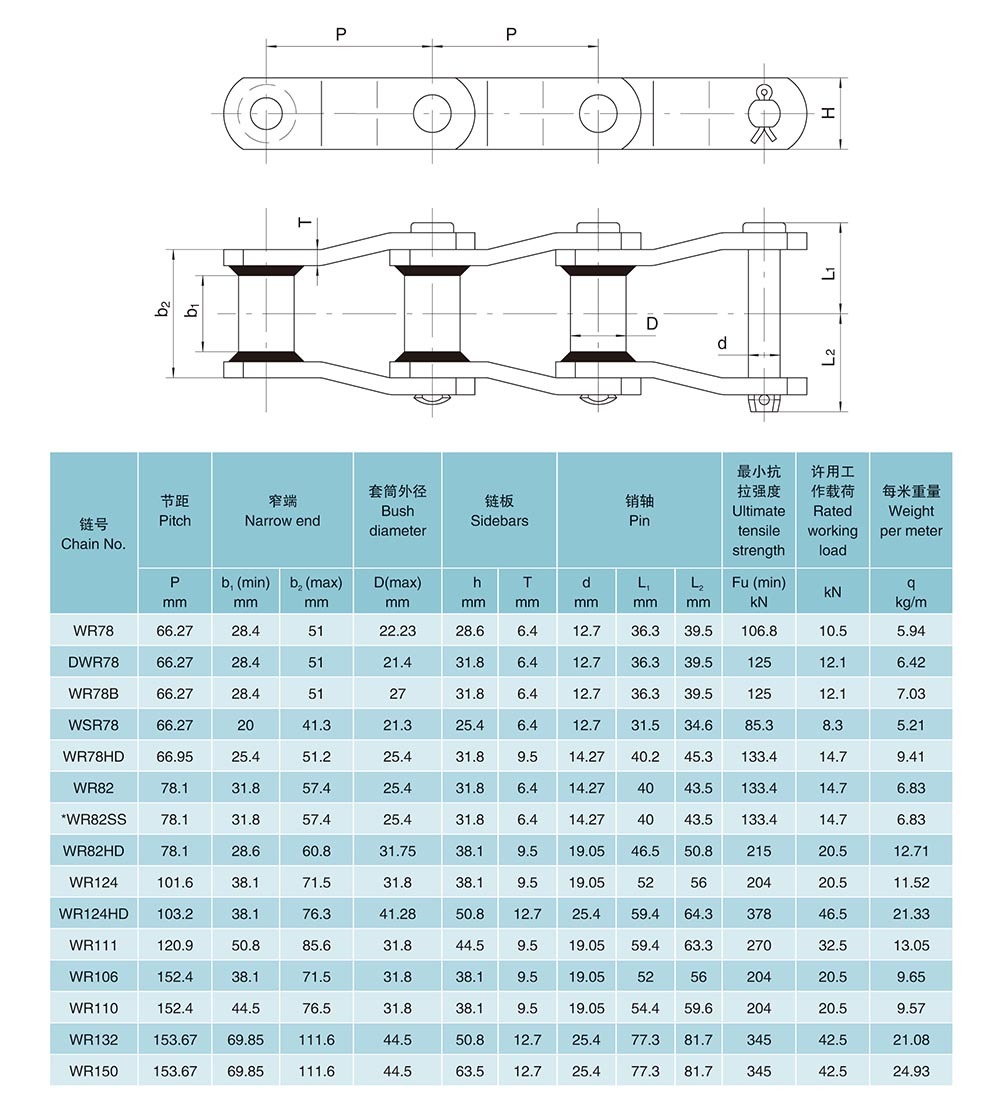

Graphic Details

WDH welded steel drag chains

UniISO equips many selected drag chains such as WDH110,116 and 480 with full round barrels. Including the WH, WHX, and WDR series chains, this seamless thick wall is almost twice the industry standard. It comes with the option of a full round press fit pin depending on chain size. The pin is in full contact with the barrel for its entire length, which gives it more load bearing surface and prevents wear. Pin-to-barrel tolerances are much tighter than standard, which increases component life. All parts are fully heat treated. The chain can also be run in any direction and will run on existing sprockets.

Welded scraper chain, also known as drag chain, is a specialized type of conveyor chain commonly used in material handling and conveying applications. It is characterized by its robust construction and welded steel links that are designed to withstand heavy loads and abrasive materials. The welded design ensures the chain’s strength and durability, making it suitable for challenging industrial environments such as mining, cement plants, and waste management facilities.

One of the key features of welded scraper chains is their ability to effectively move bulk materials like coal, ore, gravel, and other heavy items. The strong welded links are resistant to wear and deformation, ensuring smooth and reliable operation over extended periods. This type of chain is often used in scraper conveyors, drag conveyors, and apron conveyors where reliable material transport is essential for operational efficiency.

In addition to their durability and load-bearing capacity, welded scraper chains are also known for their low maintenance requirements and long service life. Proper installation and regular inspections can ensure optimal performance and prevent premature wear.

Overall, welded scraper chains are indispensable components in various industries where efficient and reliable material handling is crucial for productivity and profitability.