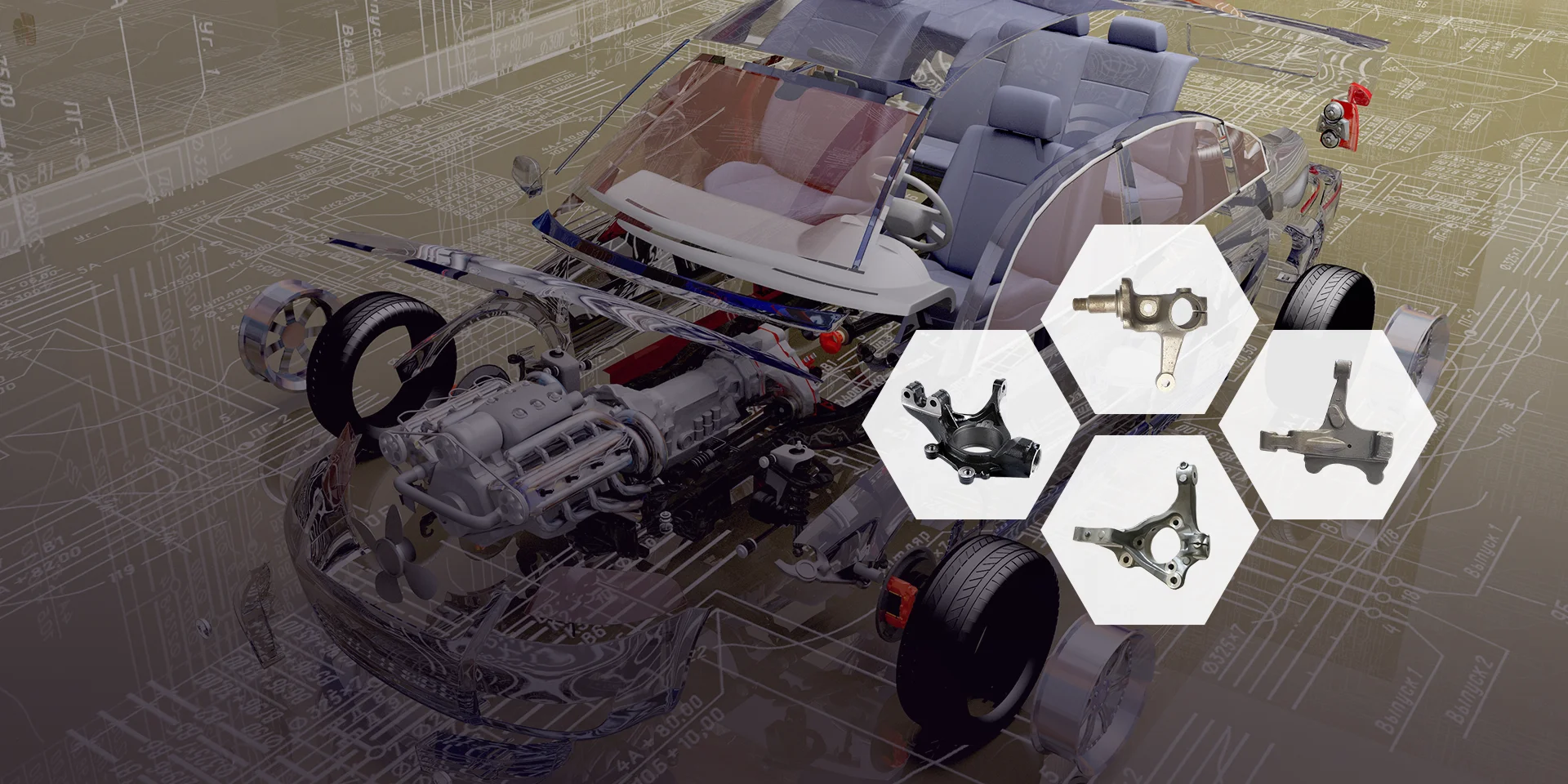

Founded in 2007, SN is a world first-class supplier of commercial vehicle control system as well as parts and accessories. Shanghai Sennai Precision Machinery Manufacturing Co., Ltd. and Shangdong Sennai Technology Co., Ltd. are subordinate to SN. SN possesses nearly 10,000m2 workshops, over 200 employees, over 100 sets of precision equipment such as forging press, punch press, CNC lathe, machining center, core-free mill, welding machine, etc. We can meet needs of diversified metal production such as precision forging, rough machining, precision machining, punch molding, welding, wire cutting, bending, etc. We mainly produce brakes, conveyor chains, high-pressure common rails, oil atomizers, door hinges, knuckles, X348, X458, X678, HT698 and other die forging chains, MS scraper chains, caterpillar chains, oil cylinder accessories, agricultural machinery accessories, etc.

Established in 2007

Plant area of nearly 10000 ㎡

More than 200 employees

More than 100 sets of precision equipment

Design Engineering

SENO leverages cutting-edge CAD/CAM software and a team of skilled technical professionals to meticulously design and fabricate molds that adhere to stringent customer specifications.

Mold Manufacturing

SENO employs advanced CNC machining and electrical discharge machining (EDM) equipment, coupled with a proficient and dedicated workforce, to internally produce and uphold all tools and molds.

Closed Die Forging

SENO maintains an unwavering commitment to the manufacture of premium closed die forgings, dedicating its resources exclusively to this pursuit on one of its 11 mechanical presses. These advanced presses span a capacity spectrum from 650 tons to 4000 tons.

Precision Machining

In addition, SENO possesses the proficiency for executing secondary and precision machining procedures, encompassing operations such as piercing, magnetic particle inspection, embossing, and cleaning. SENO stands as a reliable partner, catering to the individual needs of our clients by delivering top-notch heat treatment and machining solutions.

Quality Control

SENO has achieved ISO 9001:2008 and ISO/TS 16949:2009 certifications for its robust quality management systems.

ADVANTAGE

SENNAI Advantage

SENO holds crucial certifications in quality management systems, including ISO 9001:2008 and ISO/TS 16949, to meet customer demands and other stakeholders’ needs while complying with relevant laws and regulations. To this end, stringent production standards are implemented throughout the entire manufacturing process to ensure absolute compliance with customers' specific requirements. At each stage of production, samples are extracted, and precision measurements are conducted, guaranteeing uniform and consistent manufacturing.