X-678 Casting Chain

X-678模锻链条的主要优点是强度高、韧性好、耐腐蚀、寿命长、坚固耐用。它的主要结构是链节和销轴。链节和销轴通常由钢制成,并采用锻造成形。

Classification:

Die Forging Chain

Key words:

china Palm oil conveyor chain

china Scraper conveyor chain

china Elevator circulation chain

Shanghai Sennai Precision Machinery Manufacturing Co., Ltd

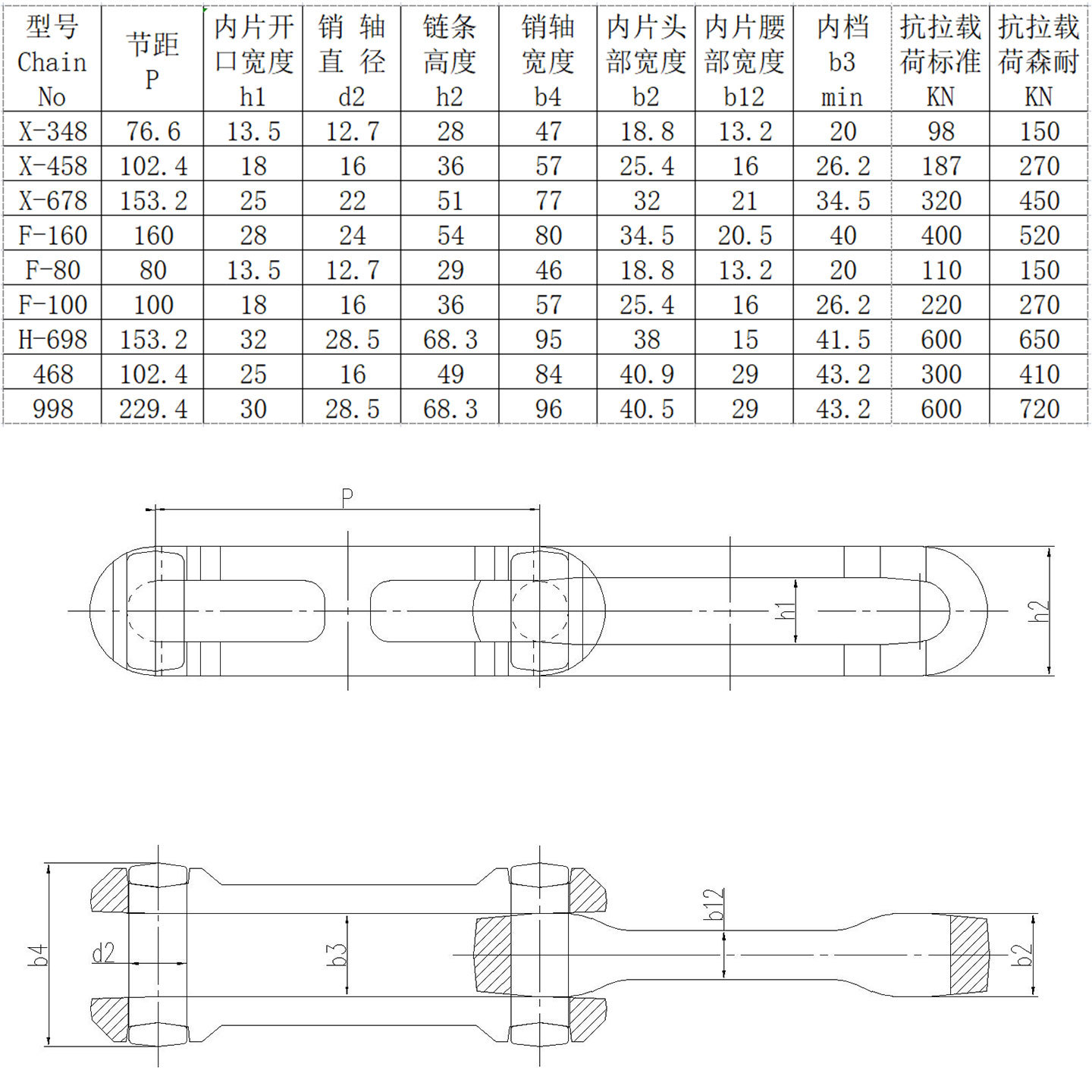

Graphic Details

X-678模锻链条的主要优点是强度高、韧性好、耐腐蚀、寿命长、坚固耐用。它的主要结构是链节和销轴。链节和销轴通常由钢制成,并采用锻造成形。

Forge chain, also known as forged chain, is a type of industrial chain that is manufactured through a forging process. This production method involves shaping the metal using localized compressive forces, resulting in a chain with increased strength, durability, and wear resistance compared to chains made using other manufacturing techniques.

Key features of forge chains include:

Strength: Forge chains are known for their high strength and load-bearing capacity, making them ideal for applications that require heavy-duty performance.

Durability: The forging process results in a chain that is more durable and resistant to wear and fatigue, ensuring a longer service life even in demanding operating conditions.

Precision: Forge chains are often manufactured to precise specifications, ensuring consistency in quality and performance.

Versatility: Forge chains can be customized to meet specific application requirements, such as different sizes, configurations, and attachments.

Forge chains are commonly used in various industries, including automotive, agriculture, mining, and material handling. They are often employed in applications where high strength, durability, and reliability are essential, such as conveyor systems, lifting equipment, and heavy machinery.

In summary, forge chains are industrial chains manufactured through a forging process, known for their exceptional strength, durability, and precision. They find widespread use across different industries that require rugged and reliable chains for heavy-duty applications.